Entretien avec Mari Kozawa, le 2 février 2021

L'industrie de la mode serait responsable de 10% des émissions mondiales de dioxyde de carbone générées par les activités humaines et serait la deuxième plus grande consommatrice d'eau. De plus, des incidents comme l'effondrement du Rana Plaza mettent en lumière les problèmes sociaux qui entourent le monde de la mode.

Face à cette situation, la recherche de pratiques de « mode éthique » susceptibles de contribuer à atténuer les problèmes environnementaux et sociaux s'est intensifiée. Au Japon, il existe une méthode traditionnelle qui promeut l'éthique dans la mode. Le kusakizome, qui utilise des teintures végétales et naturelles, est une méthode de teinture en parfaite harmonie avec le mode de vie traditionnel japonais, où l'harmonie avec la société et la nature est valorisée. Le kusakizome est utilisé au Japon depuis l'Antiquité et fait partie intégrante de la vie quotidienne.

J'ai assisté à un atelier organisé par Kyoto Kawabata Shoten, une entreprise de Kyoto qui a adopté une méthode de production kusakizome vieille de 1 500 ans. J'y ai découvert l'entreprise, puis j'ai interviewé son président, Yasuo Kawabata, sur un projet sur lequel il a travaillé avec des étudiants.

Créer des produits éthiques en utilisant la méthode Shin-Manyozome d'il y a 1500 ans

Kyoto Kawabata Shoten a été fondée en 1924 comme fabricant de kimonos. L'entreprise a cessé de vendre des kimonos en 1995, mais a continué à imprimer des textiles avec des teintures à base de pétrole, encore rares à l'époque. Cependant, certains employés souffraient de problèmes de peau dus au contact avec des teintures chimiques ou de maux de tête dus à leur odeur. La première fois que le président Yasuo Kawabata a envisagé l'utilisation de teintures naturelles, c'était lors d'une discussion avec les employés pour trouver une solution.

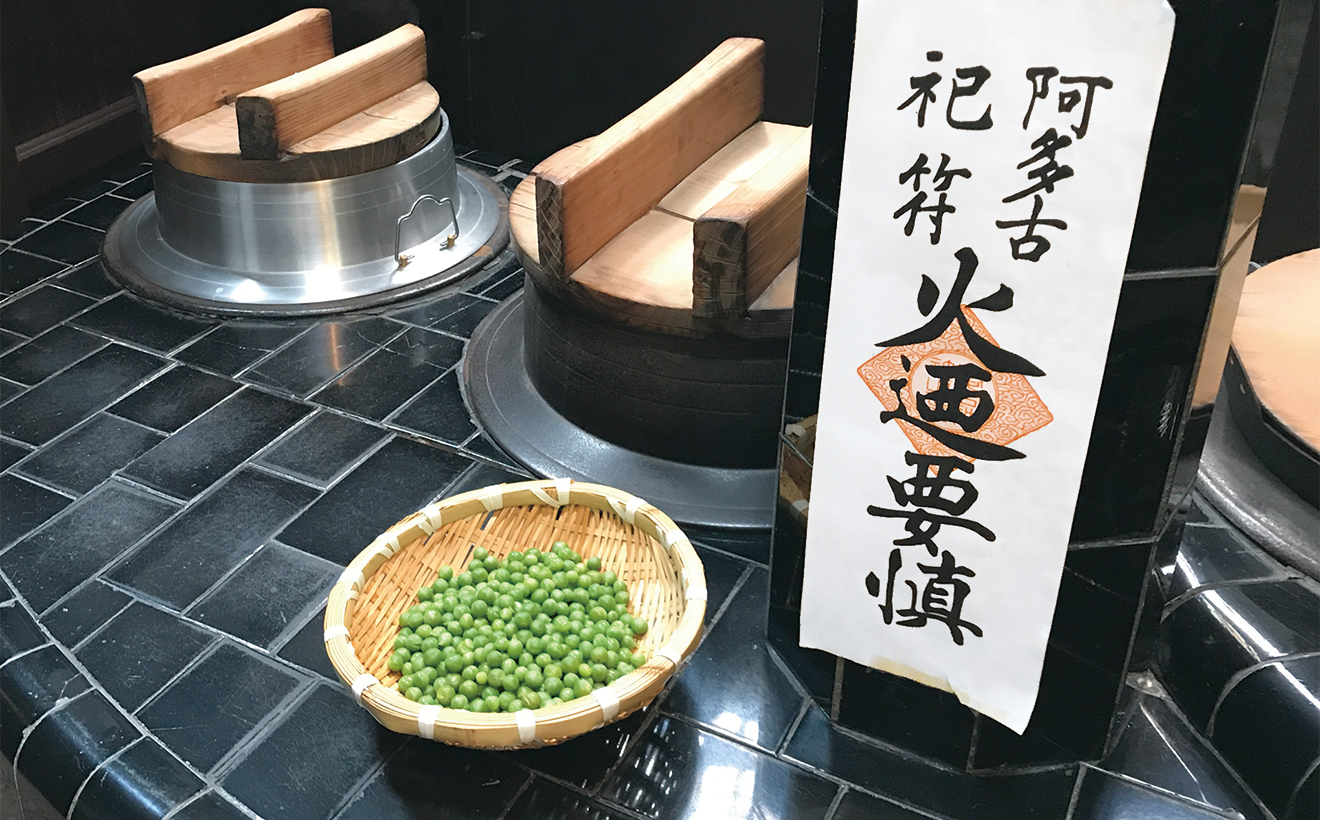

L'impression à base de colorants à base de pétrole est une méthode relativement simple et efficace, qui ne nécessite pas de compétences particulières. En revanche, elle peut avoir des effets néfastes considérables sur l'environnement et la santé humaine. Il y a 15 ans, M. Kawabata a franchi le pas et a commencé à développer une méthode de teinture kusakizome avec M. Mitsuo Kimura, professeur émérite de l'Université Mie. Le résultat est une méthode de teinture appelée « Shin-Manyozome », utilisant des matières premières naturelles telles que des plantes et des insectes. Par exemple, des couleurs vives sont obtenues à partir de soucis pour le jaune, de cochenille pour le rose et de campêche pour le bleu clair. Kyoto Kawabata Shoten vend des châles teints selon la méthode Shin-Manyozome.

La méthode Shin-Manyozome se caractérise par un temps de préparation et une teinture minimes, ainsi que par l'absence de chauffage nécessaire. Le développement de la méthode Shin-Manyozome et le passage à la teinture kusakizome ont donné de bons résultats, permettant notamment d'obtenir de magnifiques teintes impossibles à obtenir avec des colorants synthétiques. De plus, l'odeur de l'air dans l'usine s'est améliorée et les eaux usées sont devenues plus respectueuses de l'environnement, car la solution de teinture et la solution de mordant peuvent désormais être restituées à la nature.

Image de Kyoto Kawabata Shoten – De gauche à droite : arbre à pagode (blanc cassé), souci (jaune), garance indienne (garance), cochenille (rose), bois de campêche (bleu clair)

Le nouveau mais ancien Shin-Manyozome est devenu la clé pour résoudre le problème des eaux usées

À l'origine du développement du Shin-Manyozome se trouve l'intérêt de M. Kawabata pour la teinture kusakizome, qui aurait été introduite au Japon il y a plus de 1 500 ans. À la même époque, le Dr Kimura, co-développeur de cette méthode, s'interrogeait sur « comment les textiles et les fibres étaient teints à l'époque de Nara (710-784) ». Il souhaitait étudier comment la teinture était possible en l'absence d'équipement de chauffage moderne, rendant difficile de porter la solution à plus de 100 °C. (Le nom Shin-Manyozome signifie littéralement « la nouvelle teinture manyo », d'après le titre d'une célèbre anthologie de poèmes des VIIe et VIIIe siècles intitulée « Le Manyoshu)

Par ailleurs, la pollution environnementale était de plus en plus perçue comme un problème majeur lors du développement du Shin-Manyozome. À l'époque, Kyoto Kawabata Shoten pratiquait la sérigraphie, une méthode d'impression permettant d'imprimer des motifs sur textile, et était confrontée à des problèmes d'élimination des encres et des eaux usées. Afin de résoudre ces problèmes, la méthode Shin-Manyozome a été appliquée au développement d'une nouvelle méthode d'impression appelée « e Print ». Cette méthode n'utilise pas de colorants à base de pétrole ou synthétiques, mais uniquement des pigments naturels pour imprimer sur des produits tels que des t-shirts. Tous les ingrédients, y compris les matériaux auxiliaires, sont d'origine naturelle, ce qui permet de restituer les eaux usées à la nature une fois rejetées. Enfin, les résultats du développement de l'e Print ont été appliqués pour améliorer la qualité du développement des couleurs et des eaux usées de la méthode Shin-Manyozome.

Photo de : Mari Kozawa

Transmettre la méthode de teinture éthique redécouverte à la prochaine génération

Photo de Yumi Komori

À l'automne 2020, Kyoto Kawabata Shoten a lancé un projet collaboratif avec des écoles de mode de Kyoto et d'Osaka. Des soucis issus de l'agriculture biologique, destinés à être éliminés, ont été récoltés par des étudiants, conformément aux objectifs universels des ODD : « Objectif 12 : Assurer des modes de consommation et de production durables » et « Objectif 17 : Renforcer les moyens de mise en œuvre et revitaliser le Partenariat mondial pour le développement durable ». Les soucis ont ensuite été séchés et transformés en teinture, et les étudiants ont chacun créé des articles avec cette teinture. Ce projet a impliqué les producteurs, les vendeurs et les jeunes afin de créer des liens entre la technologie japonaise traditionnelle et la mode éthique.

L’industrie du vêtement du futur valorisera non seulement l’efficacité mais aussi l’éthique

Après avoir découvert l'entreprise, j'ai interviewé le président de Kyoto Kawabata Shoten, M. Yasuo Kawabata, sur le projet qu'il a réalisé avec les écoles de mode.

Photo de Yumi Komori

Qu’est-ce qui vous a amené à initier ce projet ?

En 2019, un typhon majeur a détruit les soucis qui attendaient d'être récoltés et nous avons dû prendre des mesures d'urgence pour sécuriser le matériel. Nous avons contacté les jardins botaniques et les parcs d'Osaka en leur disant : « Si vous avez des soucis que vous souhaitez jeter, veuillez nous autoriser à les récupérer. » J'ai également expliqué notre motivation : « Nous réutiliserons les déchets pour la teinture, réalisée avec les dons de la nature. » Le parc commémoratif de l'Expo 70 d'Osaka nous a ensuite donné son autorisation, avec une date précise pour la récolte. J'ai ensuite consulté le Marronnier College of Fashion Design et le Ueda College of Fashion, et ce projet a été lancé.

Récemment, de grandes entreprises de vêtements ont commencé à affirmer leur soutien à la mode éthique et aux ODD, mais je m'inquiète du manque d'enseignants capables d'aborder ces thèmes dans les écoles. Je m'attends à un fort déclin de l'activité des entreprises de vêtements traditionnelles au Japon. La méthode Shin-Manyozome est une méthode innovante qui va au-delà du kusakizome traditionnel. Lors de la planification du projet, j'espérais également offrir aux étudiants l'occasion de découvrir cette nouvelle technologie inventée par le Dr Kimura à partir d'indices issus de technologies anciennes.

Comment avez-vous vécu le travail avec les étudiants sur ce projet ? Des réflexions vous sont-elles venues à l'esprit en communiquant avec eux ?

Le processus de récolte avec les étudiants s'est déroulé sans problème et rapidement, et je pense que le branding a pris la bonne direction. J'ai donc vu le potentiel du merchandising. Bien qu'il s'agisse de notre première tentative et que nous n'ayons pas abouti à une collaboration avec des produits dérivés, j'ai pensé que cela pourrait servir de modèle de coopération entre l'industrie, le gouvernement et le monde universitaire pour des pratiques durables. Cette initiative m'a donné de l'espoir.

De plus, je pense avoir pu diffuser le concept de production respectueuse de l'environnement grâce à ce projet. Que ce soit dans le secteur de la mode ou non, les étudiants travailleront assurément dans un environnement où l'efficacité est constamment requise. Je pense que, même dans ce contexte, des pionniers de la mode opteront bientôt pour une production éthique et la pratiqueront avec brio.

Post-scriptum de l'auteur

En écoutant l’histoire derrière le développement de la méthode Shin-Manyozome, l’approche enthousiaste de M. Kawabata pour trouver des solutions aux problèmes de santé et aux problèmes d’eaux usées de ses employés, ainsi que sa quête d’une méthode de teinture éthique, m’ont laissé une impression durable.

J'ai également pensé qu'explorer et transmettre des technologies traditionnelles pratiquées depuis l'Antiquité pourrait être une approche importante pour envisager l'avenir de la mode éthique. En remontant le temps, nous constatons que nous avons toujours créé des objets du quotidien à partir de matériaux locaux. Produire dans notre environnement nous a naturellement amenés à tisser des liens avec les autres membres de notre communauté et avec l'environnement naturel.

Le manque de relations avec les autres et la nature dans la vie moderne, dû à la division du travail à grande échelle, engendrée par la priorité donnée à l'efficacité, pourrait être à l'origine de divers problèmes sociaux qui émergent récemment. Faute d'une vision claire du cycle de production et de notre relation à celui-ci, nous nuisons inconsciemment à l'environnement et aux travailleurs.

Le concept d'« éthique » dans l'industrie peut sembler novateur, mais en réalité, s'adapter aux traditions culturelles transmises de génération en génération pourrait être la première étape. Comme le dit le proverbe : « Qui veut savoir ce qui doit arriver doit considérer ce qui a été », il pourrait être judicieux de se tourner vers l'expertise traditionnelle et locale pour trouver des solutions et favoriser un avenir de production éthique.

Référence (japonais) :

Kyoto Kawabata abattu « À propos de Shin-Manyozome »

Édité par Megumi Ito

À propos de l'auteur : Mari Kozawa

Directrice de TSUNAGU. En 2018, Mari Kozawa a rejoint la marque de mode éthique TSU.NA.GU. et a promu la transparence de la mode en concevant des modèles économiques et en favorisant la communication bilatérale entre producteurs et consommateurs. Elle organise et dirige également des projets liés à la génération Z et à la promotion du bien commun.