Taichi Kondo trained under the woodworker, Kiyotsugu Nakagawa, a certified Living National Treasure (a title given by the Japanese government to exceptional holders of important intangible assets), and set up his career as an oke artisan (a Japanese cooper that specializes in making traditional wooden buckets/pails and other items made using related techniques). As a successful artisan, Mr. Kondo has had his guinomi sake cups, and ohitsu rice tubs made with his outstanding mastery of woodworking skills been introduced in magazines and sold in shops like the D&DEPARTMENT KYOTO by Kyoto University of Arts and Designs, and KYOTO OKAZAKI TSUTAYA BOOKS.

The way he works in his Japanese-style work clothes, surrounded by countless wood planes in his workshop in Murasakino (the northern area of the town of Kyoto), perhaps matches the picture exactly of what you would imagine an artisan of traditional craftworks is supposed to look like. Although someone might feel shy about approaching him and feel intimidated, such worries will soon disappear with his friendly smile. He is the kind of person that younger artisans would go to for help. This time, Mr. Kondo shared his open opinions on the current demand of oke and the connoisseur features of the woodworks.

Taichi Kondo at his workshop

Taichi Kondo/Oke Artisan(Cooper)

Taichi Kondo was born in Osaka in 1973. He received his degree from Kyoto Seika University Graduate School. From 2002, he started training under woodworker, Kiyotsugu Nakagawa and specialized in cooping and joinery skills. In 2009, he completed his apprenticeship and set up his own workshop, Okeya Kondo (Cooper Kondo). He was certified as a Traditional Craftsperson of Kyo Sashimono (Kyoto joinery) in 2016.

—– Is it true that you started out as an artist-sculptor?

Yes. I went to Kyoto Seika University and went on to graduate school, and then after I completed my degree there, I worked at Osaka University of Arts as an assistant. Alongside helping students, I made my own works mainly out of plastic or textile materials using the facilities of the University. I had solo and group exhibitions from the late 90’s, but after I finished my job at the University, I experienced an encounter that completely changed my course of life.

—– What was that encounter that completely changed your life?

It came my way in 2002 when I finished my contract with Osaka University of Arts. An older graduate of my alma mater, the third generation of Nakagawa Mokkougei (Nakagawa Woodworks) Shuji Nakagawa asked me, “What have you been doing these days?” and I said, “ I just finished my university job and I haven’t been doing anything.” Then he said, “What a waste. You’ve got to be making something. Come over and help out!” At that time, I had no connections with traditional craftwork. I was completely ignorant. I just went there thinking casually, that it would be a part-time job… and then, I was struck by lightning. It was the real thing: it was the site of a real artisan using his hands, making a good-old, Japanese wooden oke. I didn’t even know that “the master,” Kiyotsugu Nakagawa, was a “Living National Treasure” until I started working there. (laughter)

—– So you started the part-time job, not knowing that Kiyotsugu Nakagawa was a certified Living National Treasure! How were you able to become his apprentice?

Well, after I finished the month-long part-time job, I asked him, “Please let me continue!” I thought that he made the most beautiful oke in Japan, which means, surely the best in the world. I was so powerfully inspired (by his work). Then, I trained under him for seven years. At first, he wouldn’t even call me his apprentice, but I did everything I could to keep up, though my skills were limited at the time. When I started working at his workshop, I was 29 years old. That’s really late in the world of traditional craftworks, because it used to be the custom to start training instead of going on to higher education. So I was certain that I wouldn’t be able to accomplish anything unless I did above expectations, so I really devoted myself to my work.

Mr. Kondo showing how he makes his best-seller “Guinomi (sake cup)”

—– I understand that when you say “mokkougei (woodwork)” it could mean many things, from vessels to cabinets. What sort of items are included in the category of “oke”?

Woodworks can be divided by the methods used in their production. Things that assemble pieces of wood together are called “Sashimono (joinery),” and things that bend the wood, such as in wappa (round chip boxes), are called “Magemono (literally ‘the bent’).” There are also things that are made by hollowing out the wood by chisels called “Kurimono (literally’ the hollowed’),” or things that are turned on lathes called “Hikimono (turnery).” The making of oke uses hoops, so it’s called “Tagamono (literally ‘the hooped’).”

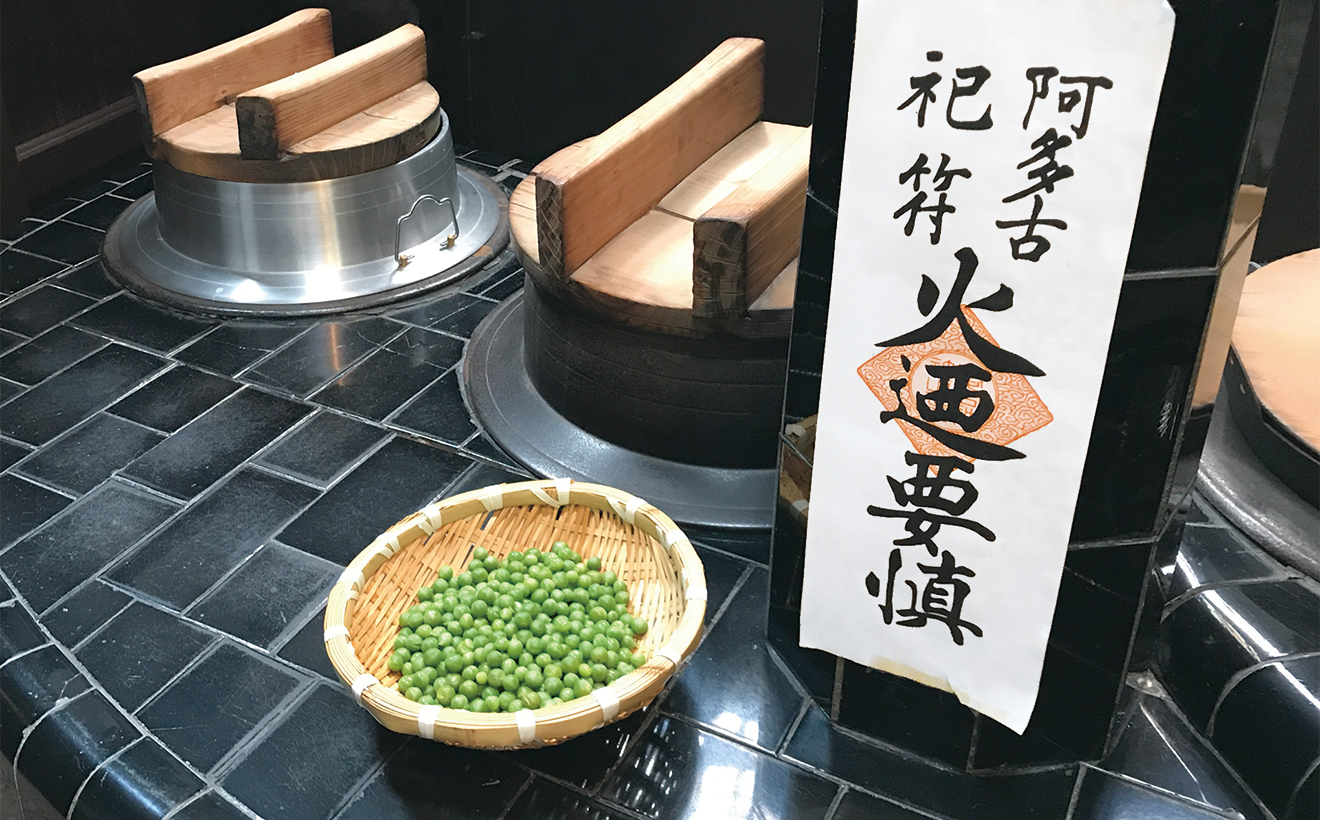

Out of the variety of oke, items such as sushi rice tubs, bath buckets, lidded rice tubs, and laundry basins were made to be used in ordinary households. But, nowadays, these items are substituted by things like plastic buckets or electric rice cookers, so they are not commonplace anymore. There’s an increasing number of young adults that appreciate cooking their rice in earthen pots and serve it from a lidded rice tub (like the old days). But, I haven’t come across anyone who wants to do their laundry in a laundry basin. I suppose that’s too much work. (laughter)

—–Then where is the demand for oke in the modern days?

The demand still exists. Thankfully, there are still people who say that they want to use what has been used since a long time ago. There are people who come to me because they want their’s repaired or have the same thing made anew. I think there are relatively many people like that in Kyoto.

We also get orders related to temples and shrines (Kyoto has thousands of them). Typically, the teoke (handled buckets for water) and the hishaku ladles used for the water basins for purification. I’m also often asked to repair or make votive objects that I’ve never even seen before. The most puzzling piece, among such, was an oke with no lid nor bottom. I was asked to make the exact same thing “because it’s needed every day.” That mysterious object turned out to be used to stuff the rice for offerings inside, and then slip it off, like a mold. Probably the artisan who made it quitted his job or passed away, so the client came to my master. Then, after completing one, the client asked for another. I asked, “Why do you need to have two of the same thing?” and the client said, that they wanted to have “a spare” because “a temple is sure to stay forever, but we never know when a cooper will close the business, so we’ll keep one more, just for in case.” Who else in the world would think in such a long time span (laughter)?!

There are many planes and other tools in the workshop. The broom from the Naito Shoten shop on the west corner of the Sanjo Bridge (downtown Kyoto) is a must-have item for cleaning the workspace.

—– I see that you have a great collection of tools. Do you actually use all of these?

There are some that I use all the time, and some that I rarely use, but it’s necessary to have a wide variety of planes ready. For example, have you noticed that a typical oke is wider at the top and narrower at the bottom? This means that we have to use planes with different curves for the upper parts and the lower parts of the same oke because they each have different curves. At least 3 – 5 different planes for the outer side alone, plus there’s the inside and the edges. Even making a small guinomi sake cup would need 8 – 9 different planes.

—– How did you collect all these tools?

In my case, I don’t come from a long line of artisans, so I started buying and collecting my own since I was an apprentice. I collect planes sold at antique markets that were abandoned by artisans that discontinued their trade. The planes have histories to themselves, so if you just look at my tools, you’d think my workshop is a long-established one (laughter). It’s not that I can’t afford new tools, but because there are not many artisans that make oke, there are very few artisans that make the kind of planes that oke artisans use. Which is also why I need to sharpen the iron, and fix the base of the planes myself. I have to teach myself how to sharpen well and learn how to find a way to best exploit each tool that are all slightly different from one another. After carefully studying each tool for many days, wondering about “why it’s sharpened in this particular way” or “why the base is adjusted like this,” sometimes the moment of enlightenment comes when I think “This is it! This must be the way to use this!”

The same can be said for when I repair other artisan’s works. I am sometimes puzzled, thinking, “Why did the artisan assemble this piece in this way?” And when I look at a damaged part, I think, “So, this is what happens decades later, when you assemble it the wrong way.” Repairing is case-studying. It’s also reassuring to see that, when craftworks are used as they were intended, they can be kept in use for ages. It makes me feel that I can’t make anything that I would feel ashamed of when a future artisan would repair it.

Using a plane customized for shaving the inside of the oke

—– What features of an oke would an oke master take most pride in?

Well, there are many features worth mentioning, but first of all, the material: Whether it uses wood of fine grain. And, whether the grains are taken vertically to the rings. It’s ideal that the grains of each slat comprising one oke look alike, so they look united as a whole. As you probably know, wood can shrink over the years: if there’s one slat with rough grain among fine-grain slats, then it would cause the whole piece to become crooked. So, even if the wood comes from the same tree, it’s essential to pay close attention to the different qualities of different parts from the grain and color.

Kyoto’s oke are characterized by subtle chamfering. Their refined look comes from the modest roundness of the edges created by shaving off the edges slightly. When the shaving is too obvious, it’s no good, but just the right amount of shaving creates a light feeling because of the reduced contact with the surface it is placed on. We even have a name for the slightest chamfering, that’s only discernible by the touch of hand: it’s called the “hand-rub chamfer.”

Sen is a tool used for the rough-shaving process

—– What is this two-handled tool (photo above) used for?

That’s called “sen” (a Japanese two-handle drawknife), and it’s used for rough-shaving the wood. At first, the wood is supplied in the form of logs. First, the log would be chopped by a hatchet and left exposed to the weather until it’s completely dry. Then, the dried wood is roughly shaved by this sen, before the planes are applied. The sen is chosen accordingly to the curve of the wood.

—– Do you really do everything from scratch, like cutting out boards from a log?

Cutting out “boards”? Hmm… I don’t cut out “boards.” Why would I cut out something flat to make something round? I would have to waste a lot of wood if I cut out curved slats from a square board, don’t you think? Here, let me show you how I do it.

See that part of the workshop floor like a tree stump? That’s called a waridoko (literally “chopping floor”), and it’s where we place the log to be chopped. Then, a curved hatchet called warigama is applied vertically to the rings of the tree, so straight grain will be achieved, and many curved pieces of wood will be cut out. When there are knots in the log, that part would be taken out in this process.

This process of producing the material parts is called kidori (literally “wood taking”) is perhaps the most crucial part of oke making. It was only in the very last days of my apprenticeship that I was allowed to take charge of this process.

An inexperienced artisan would not be able to get many straight grain pieces from one log. To be efficient, and be able to get the maximum amount of wood pieces with good grain from one block of wood, requires an enormous amount of knowledge and experience with wood. If you could only get four pieces out of the block that you should get six, then that directly affects your revenue, right? Since we are making the highest quality products, we use an abundance of luxurious material; however, at the same time, we must take care not to waste such precious materials.

—- Thank you very much. Finally, please enjoy the video of Mr.Kondo in the kidori process!

Okeya Kondo

Address: 64-2 Murasakino Unrinin-cho, Kita-ku, Kyoto

Tel: 075-411-8941

URL: https://oke-kondo.jimdo.com

ATTENTION: The location written above is the workshop address. It is not a shop, so if you wish to visit the artisan, please contact prior to your visit and make an appointment.